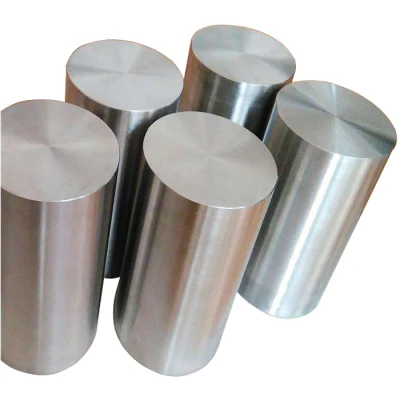

Forged Clad Tube Sheet Forging Discs and Baffel Plate for Heat Exchanger

We have rich experience in machining various heat exchanger tube sheets, baffles, special tube sheets for power stations

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | forged parts |

| Material | Alloy |

| Application | Metal Casting Machinery, Heat Exchanger |

| Heat Treatment | Avaliable |

| Forging | Avaliable |

| Titanium | Avaliable |

| Copper | Avaliable |

| Transport Package | Pallet |

| Specification | customized |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 100000ton/Year |

Product Description

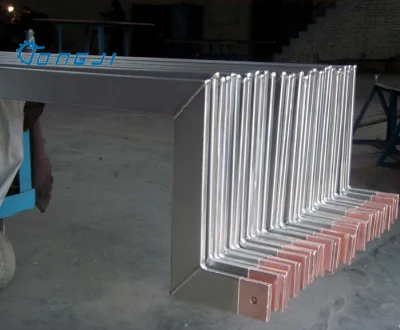

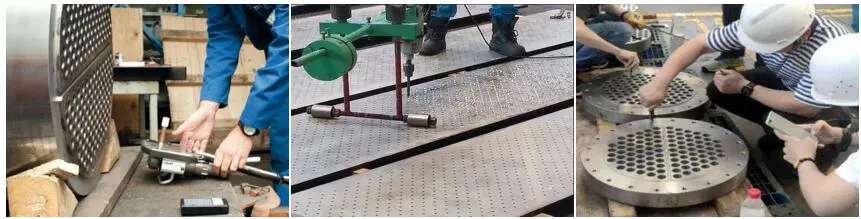

We have rich experience in machining various heat exchanger tube sheets, baffles, special tube sheets for power stations, etc. The materials we produce include duplex stainless steel, titanium alloy, forged carbon steel and so on. We are also able to manufacture and process according to specified standards such as ASME. Our company is equipped with full series of advanced tube sheet processing equipment, such as multi-hole drilling, deep hole drilling, and we also have semi-automatic chamfering processing equipment, which can shorten the construction period.

In order to ensure that the quality perfectly meets the requirements, all the tube sheets we produce need to go through the first inspection process after machining process finished to ensure that the dimensions, hole accuracy and other dimensions are up to standard. Besides, we will arrange special personnel to inspect all holes with a pass-and-stop gauge. For products with stricter requirements, we will use CMM testing equipment to further test all parameters and provide relative inspection reports to the customer.

Heavy Metal Fabricating and Machining

We are a fabricator of high precision medium to large heavy equipment parts and mechanical assemblies.we offer a competitive advantage to the heavy equipment industry with state-of-the-art metal fabrication, vast welding experience, precision CNC machining, complete assembly services, on-time delivery, and unmatched customer service.

- Full-Service Fabrication - metal cutting and sheering, metal forming, bending, and rolling, welding, CNC machining, sheet metal assembly, and quality inspection

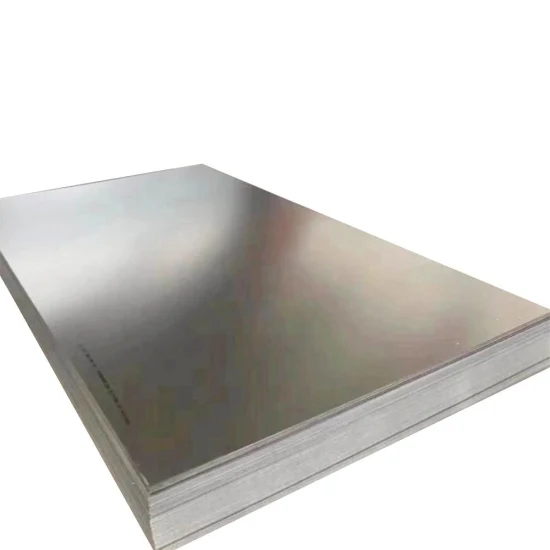

- Experts working with aluminum, abrasion resistant plate, armor plate, carbon steel, heavy plate, high-alloy steel, iron, manganese, nickel-based alloy, sheet metal, stainless steel, structural steel, and other metallic alloys

YXF Metal was founded in 1999, our factory currently has more than 1600 employees, covering an area of over 1,00,000 square meters, which has four sections: Equipment Assembly Dept., Metal Fabrication Dept, Precision CNC Machining Dept, Casting and Forging Dept.We provide full service fabricating service , from material supply, cutting and forming, rough machining, finish machining, welding assembly, and surface treatment, to the final packaging and transportation.Being as a large capacity machine shop, we have equipped a series of multiple CNC machines for both vertical and horizontal manufacture enable us to machine complex components of a large array of sizes. Our machining workshop has advanced 30-meter and 26-meter double gantry machining centers, which can basically process the precision milling and boring requirements of even the largest workpieces in various industries all around the globe.

We have a series of imported CNC Machining equipment, including large gantry machining center, horizontal boring and milling machine, turning and milling center, large vertical lathe machining center, heavy horizontal lathe machining center, dmulti-hole drilling deep hole drilling and other machining equipment facilities.Our processing capabilities are as follows:

| Gantry Machining Center | Max Height:4000mm | Max Width:4500mm | Max Length: 30000mm | ||

| Large Boring Mill | X: 15000mm | Y:4000mm | Z+W:900+1000 mm | Max Weight: 250T | Bore Tool Dia: 280mm |

| Truning and Milling center | Height: 4500mm | Weight: 350T | Max Diameter:11000mm | ||

| Vertical Lathe | Height: 4000mm | Weight: 50T | Max Diameter: 5000mm | ||

| Horizontal Lathe | Max Length: 12m | Weight: 50T | |||

| Deep hole drilling | X:3000mm | Y:2500mm | Z:700mm | Hole Dia: 16-80mm | Depth: 700mm |

| Multi-hole drilling | X:7000mm | Y:3000mm | Z:700mm | Hole Dia:2-120mm | Depth: 320mm |

Our sheet metal fabrication workshop equipped with a series of cutting machines, including laser cutter, flame cutter, plasma cutter, and wire cutting machine, but we also work with our partner who equipped with much bigger cutter than can help us work with even the largest workpiece, with these advanced CNC machines we can cut the materials with high efficiency and high accuracy.

| Laser Cutting | Plasma Cutting | Flame Cutting | Water-jet Cutting | |

| Cutting Depth | 25mm | 100mm | 450mm | 250mm |

| Cutting Width | 3500mm | 4000mm | 6000mm | 3500mm |

| Cutting Length | 28000mm | 20000mm | 20000mm | 10000mm |

| Accuracy | ±0.2mm | ±1mm | ±0.8mm |

Our forming processing platform covers large bending machines, thick plate rolling equipment, transverse shearing and slitting equipment, and leveling machines. We offer a wide range of metal forming and bending services. From sinple aluminum channels or complex metal bending for large project, we can always meet your requirements. Our large press braking machine is with max 5000Ton in capacity, and we can bend the steel plate up to 15m in length.

| Bending | Press braking capability: | 2000Ton | Max Bending Length: | 15000mm | ||

| Plate Rolling | Max rolling width: | 3000mm | Max Rolling Thickness: | 150mm | ||

| Shearing | Thickness: | 0.4-33mm | Shearing Length: | 1000-4500mm | Anti-twist (W:T) | 5:1 |

| Leveling | width: | 100-2350mm | Thickness: | 1-40mm | Accuracy: | 0.5mm/1m |

We have a complete welding platform, including plasma welding, robotic welding, TIG welding, laser welding, hand arc welding, and submerged arc welding equipment clusters.Welding methods include tube-sheet strip surfacing, automatic submerged arc welding, carbon dioxide gas shielded welding, argon tungsten arc welding, electrode arc welding, plasma welding, etc. The materials that can be welded are carbon steel, alloy steel, stainless steel, and non-ferrous metals such as copper, aluminum, and titanium.To ensure that the quality strictly meets the requirements, we have special quality inspectors to supervise and review the product quality for all projects, and we are equipped with a variety of inspection methods. For welding, we have magnetic particle inspection, X-ray inspection and other methods to inspect the weld quality. For precision machined products, we use advanced three-coordinate testing equipment to check product size, flatness, parallelism, concentricity, etc. For precision machined surfaces, we will also use special testing equipment to check that the surface roughness perfectly meets the acceptance criteria. Moreover, we will custom make inspection methods to serve for their project.

We have rich experience in manufacturing precision metal components for all kinds of applications, such as tube sheets, machine bed, power station energy storage finishing tanks, and even CNC parts for medical industry etc.

Industries we served: Construction machinery, printing and dyeing, food machinery, new energy environmental protection, nuclear power equipment, pressure vessel, etc...

Why Us?

1. Quality System: We has established a sound quality management system, and has passed different kind of welding production certification, such as the following:

2. Rich Experience: With 20 years of extensive experience in sheet metal fabrication, we have honed our skills and expertise in delivering top-quality results. Our deep understanding of the process ensures that we can efficiently handle a wide range of fabrication projects.3. Strict Manufacturing Control: We have successfully undertaken numerous overseas sheet metal projects, enabling us to be well-versed in international welding and ISO standards. Familiarity with standards like ISO 5817-c(for welding),ISO 2768-mK (for machining) ensures our adherence to strict quality guidelines. 4. Flexible in Using Equivalent Steel: We are also knowledgeable about the differences in metal material grades between different countries. This allows us to identify equivalent domestic GB standard steels with similar performance characteristics, reducing costs. Furthermore, we can substitute foreign materials specified in drawings with domestically available profiles that match the required dimensions and performance, leading to further cost savings.5. Quality Control: We maintain stringent requirements for our production workers and quality inspectors, ensuring that every product meets or exceeds industry standards. We pay meticulous attention to detail, preventing issues such as dimensional deviations, material deformation, weld defects, surface damage, and more. To provide our clients with complete confidence, we offer detailed photographs and videos of the finished products before shipping, allowing for further confirmation.6. Comprehensive Inspection Method: We provide inspection services for metal fabrication and machining. In addition to common caliper measurements, we offer CMM (Coordinate Measuring Machine) inspections to meet precision requirements down to the micron level. For large and complex structures that are challenging to inspect, we develop customized fixtures to ensure accurate dimensional measurements. We also provide welding inspection reports for high-quality welding, detailing inspection dimensions of all weld seams, including the presence of weld porosity, slag, undercutting, and other issues. Furthermore, we offer non-destructive testing specifically for weld seams, including Magnetic Particle Testing (MT) and Ultrasonic Testing (UT), among others.